Popis

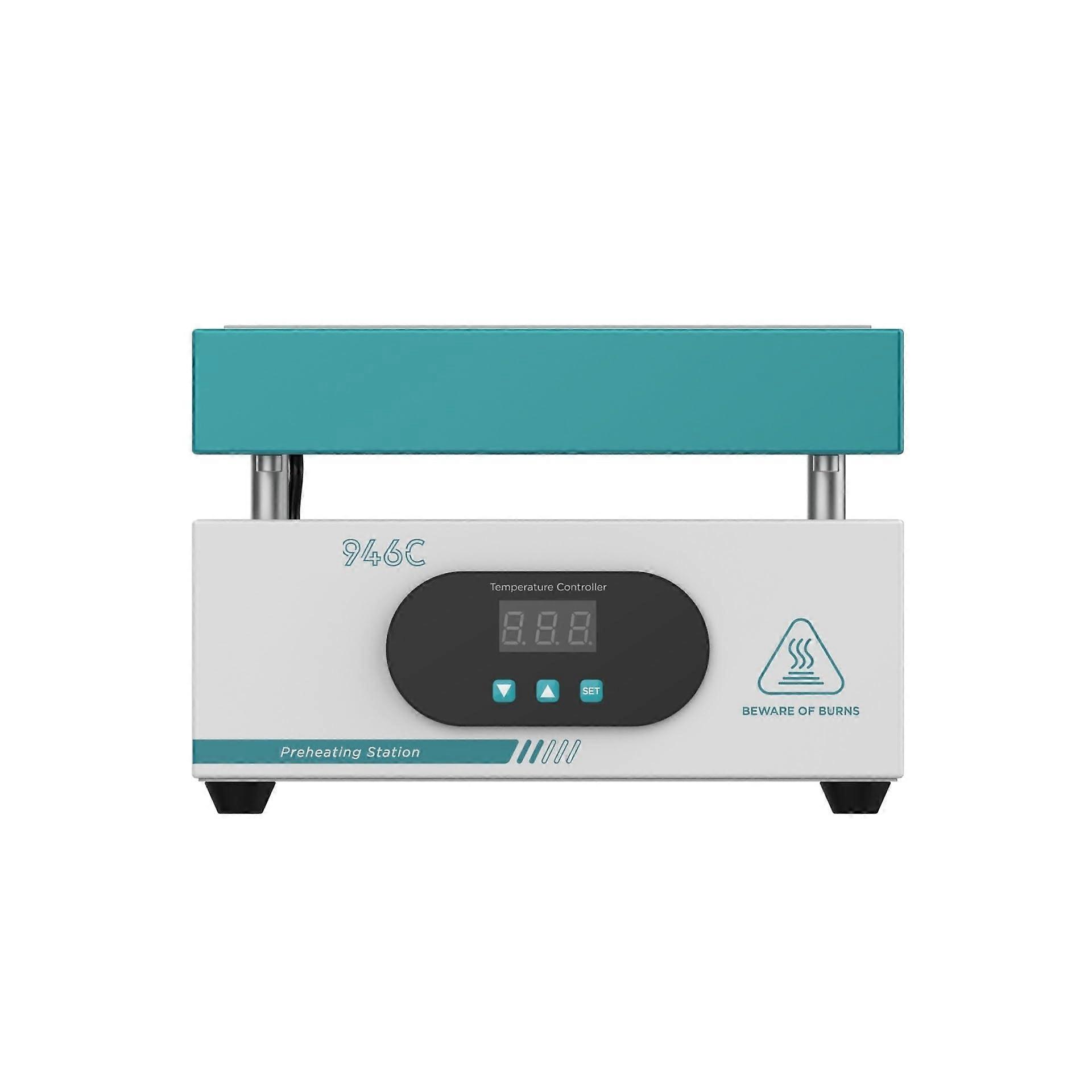

850W LCD Hot Plate Preheating Station for Phone Screen and Soldering Model

Key benefits and why you need this product

Precise, stable temperature control: an onboard processor continuously monitors and adjusts the heater to keep set temperature steady, reducing material waste and process variability.

Faster, more even heating: the aluminumalloy heating plate provides thermal efficiency and uniform temperature across the surface, shortening warmup time and eliminating hot spots.

Easy to install and operate: straightforward mounting and intuitive controls get the unit running quickly with minimal setup.

Reliable sensing and display: an accurate temperature display and automatic sensor detection make configuration simple and reduce the risk of incorrect sensor wiring.

Main functions and attributes

Temperature control: Processorbased, continuous feedback loop for precise regulation.

Adjustment modes: Two configurable modes — standard (constant setpoint) and timed (temperature control by time intervals) to suit steadystate or timesequenced processes.

Display and sensing: Intuitive, accurate temperature readout. Unit detects the temperature sensor automatically on startup or connection.

Heating element and material: Heating plate made of aluminum alloy for thermal conductivity, efficient heat transfer, and uniform temperature distribution over the plate.

Controls: Enter general temperature setting mode by pressing the * button for more than one second. While in setting mode, press * to change the number of digits of the temperature value to be set, then adjust the value using the heating or cooling buttons.

Installation: Designed for simple installation; the heater assembly and controller interface are accessible for rapid integration.

Performance and compatibility notes

Performance: Continuous processor control combined with the aluminumalloy plate yields consistent heating performance and minimal temperature fluctuation during operation.

Compatibility: Intended for integration with systems that require an external heater and sensor connection. The unit supports automatic sensor detection to simplify controller pairing. Verify electrical and mechanical connections against your system specifications before installation.

Size and form factor: Compact, platestyle heater suitable for confined workspaces; check your mounting and clearance requirements to confirm fit.

Typical applications

Electronics rework and soldering: Maintain a stable, uniform temperature for board preheating, component reflow, or BGA work where controlled heat prevents thermal damage.

Smallscale laboratory heating: Suitable for sample warming, incubation of small parts, or experiments requiring steady temperature control with timed cycles.

Light manufacturing or benches: Use for adhesive curing, part preheating, or process steps where precise, repeatable temperature profiles and timed control improve yield.

How it solves common problems

Prevents overheating and thermal spikes thanks to continuous processor control.

Reduces uneven heating issues with a efficiency aluminumalloy plate.

Lowers setup errors by autodetecting the sensor and providing a clear temperature display.

Simplifies configuration with two practical control modes (standard and timed) and a clear procedure for setting temperature digits and values.

User setup summary

Install the heater plate according to your mounting and electrical requirements.

Connect the temperature sensor and power — the unit will automatically detect the sensor.

To set the temperature: press and hold * for more than 1 second to enter setting mode. Press * to select how many digits of the temperature value to edit, then use the heating or cooling buttons to increase or decrease the temperature to the desired value.

Choose between standard mode for constant temperature or timed mode for timebased temperature control as required by your process.

This product provides controlled, uniform heating in a compact assembly with simple installation and clear controls, making it suitable for electronics, lab, and light manufacturing applications where reliable temperature management is essential.

-

Fruugo ID:

444100720-932673044

-

EAN:

6162390840049

Doručení a vrácení

Odesláno do 24 hodin

Doprava od Čína.

Děláme, co můžeme, aby k vám produkty, které si objednáte, dorazily kompletní a splňovaly vaše specifikace. Pokud však objednávka dorazí nekompletní, produkty jsou rozdílné od těch, které jste si objednali, nebo existuje jiný důvod k nespokojenosti s objednávkou, můžete objednávku nebo jakékoliv v ní obsažené produkty vrátit a obdržet za ně plnou náhradu. Zobrazit kompletní zásady vrácení