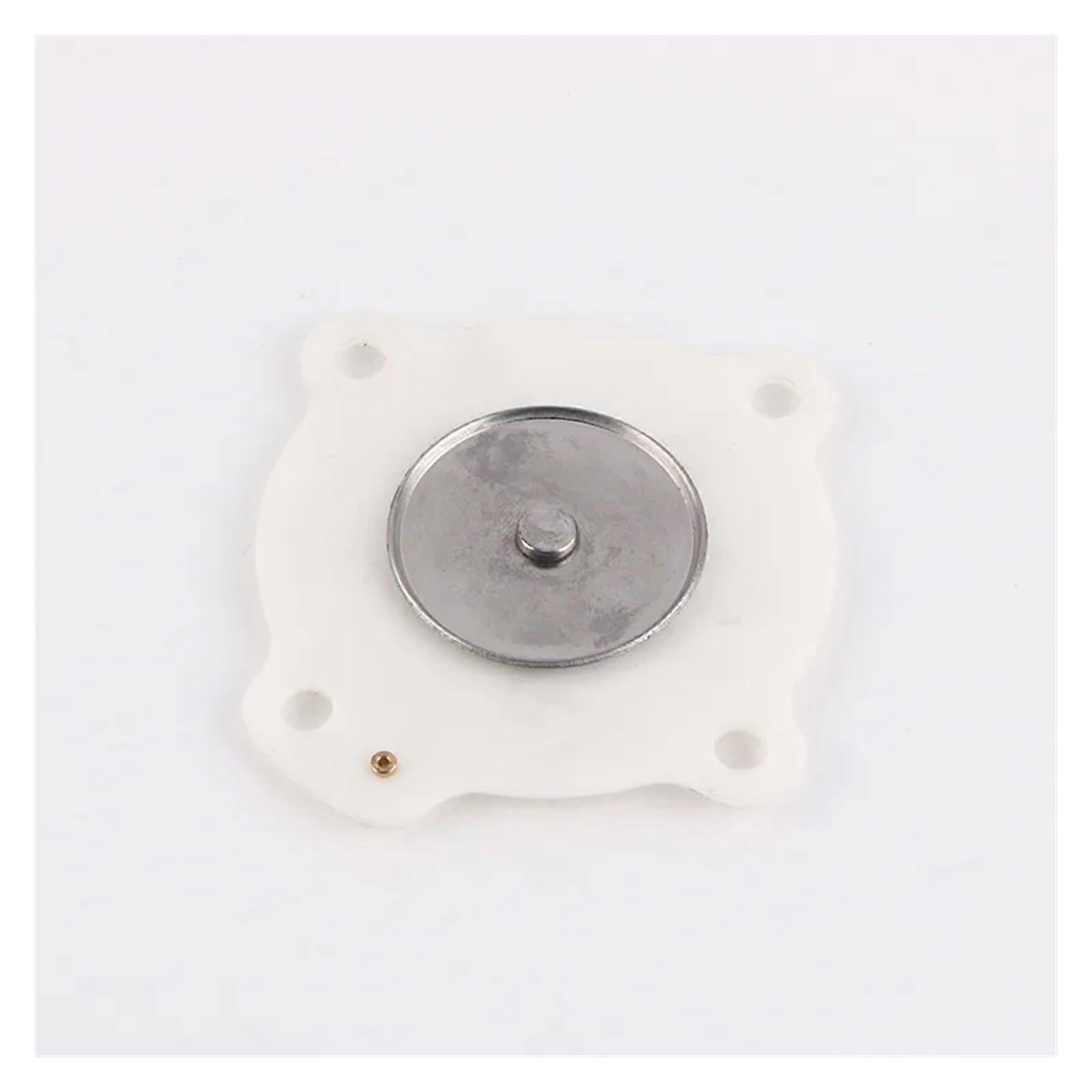

Electromagnetic Pulse Valve Diaphragm SCG353A044 A043 Dust Removal Valve Diaphragm

doprava ZDARMA

Electromagnetic Pulse Valve Diaphragm SCG353A044 A043 Dust Removal Valve Diaphragm

- Značka: Unbranded

Electromagnetic Pulse Valve Diaphragm SCG353A044 A043 Dust Removal Valve Diaphragm

- Značka: Unbranded

Uložit 325,00 Kč (32%)

Doporučená cena

Uložit 325,00 Kč (32%)

Doporučená cena

Přijímáme následující platební metody

Popis

Electromagnetic Pulse Valve Diaphragm SCG353A044 A043 Dust Removal Valve Diaphragm

- Značka: Unbranded

- Kategorie: Instalatérské ventily

- Fruugo ID: 375907553-813574527

Informace o bezpečnosti produktu

Přečtěte si prosím níže uvedené informace o bezpečnosti produktu specifické pro tento produkt

Následující informace poskytuje nezávislá třetí strana prodejce tohoto produktu.

Doručení a vrácení

Odesláno do 24 hodin

-

STANDARD: ZDARMA - Doručení mezi út 09 prosince 2025–čt 25 prosince 2025 - ZDARMA

Doprava od Čína.

Děláme, co můžeme, aby k vám produkty, které si objednáte, dorazily kompletní a splňovaly vaše specifikace. Pokud však objednávka dorazí nekompletní, produkty jsou rozdílné od těch, které jste si objednali, nebo existuje jiný důvod k nespokojenosti s objednávkou, můžete objednávku nebo jakékoliv v ní obsažené produkty vrátit a obdržet za ně plnou náhradu. Zobrazit kompletní zásady vrácení

Podrobnosti o shodě produktu

Přečtěte si prosím níže uvedené informace o shodě specifické pro tento produkt.

Následující informace poskytuje nezávislá třetí strana prodejce tohoto produktu.

Výrobce:

V následujících informacích jsou uvedeny kontaktní údaje na výrobce příslušného výrobku prodávaného na Fruugo.

- DelightDew

- Shenzhen Tumi Technology Co., Ltd.

- 202-03, Jinhe Building, 8 Xinhe Street, Maan Tang, Bantian

- Longgang, Shenzhen, Guangdong

- China

- Shenzhen

- CN

- 518129

- pettynfnef@outlook.com

- 13332965772

Odpovědná osoba v EU:

V následujících informacích jsou uvedeny kontaktní údaje na odpovědnou osobu v EU. Odpovědná osoba je určený ekonomický subjekt působící v rámci EU, který je odpovědný za dodržování požadavků stanovených pro příslušný výrobek prodávaný do Evropské unie.

- Synertrade FR SAS

- Synertrade FR SAS

- 9 rue du Bat d'Argent

- Lyon

- France

- Lyon

- FR

- 69001

- info@syner-sarl.cn

- (+33)774555006

- https://seller.kuajingmaihuo.com/settle/qualification-service